What is the die cutting? What is it used for?

Die cutting is the process of using a die to shear webs of low-strength materials such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam and sheet metal. In the metalworking and leather Industries, the process is known as clicking and the machine may be referred to as a clicking machine. When a dinking die or dinking machine is used, the process is known as dinking; commonly produced items using this process include gaskets, labels, corrugated boxes, and envelopes.

Die cutting can be done on either flatbed or rotary presses. Rotary die cutting is often done in line with printing. The primary difference between rotary die cutting and flatbed die cutting is that the flatbed is not as fast but the tools are cheaper. This process lends itself to smaller production runs where it is not as easy to absorb the added cost of a rotary die.

For those who are not familiar with this industry, they do not have any idea for die-cutting, what is it used for? What’s the function? Foshan Jintuo Adhesive Products has many years of professional experience in foam tape production and die cutting processing, and share it with everyone: In fact, the die-cutting is the paper products or adhesive products processing, limited to the size of the mold, the material will be cut into specified shape through the equipment or artificial cutting, that is the die-cutting. Now the die cutting application is very extensive.

Die cutting applications:

With the continuous development and expansion of the electronics industry, die cutting has not only limited the printed matter, also commonly used in electro-acoustic, medical care, display signs, security, transportation, office supplies, electronic power, telecommunications, industrial manufacturing and other industries. On the one hand, there are many products for mobile phones, digital cameras, cars, etc. Bonding (3m tape die cutting), on the other hand, it is used for a variety of equipment, dust, protection (protective film) and so on.

3M die-cutting process:

Die-cutting materials are rubber, double-sided tape and foam, plastic and so on. 3M tape due to the wide range of applications, technology innovation has brought the development, making 3M double-sided adhesive tape also applied to the die-cutting industry. Many products are fixed by 3M double-sided tape, such as air-conditioned display it can be firmly fixed in the air-conditioned body because the display has a double-sided adhesive tape in order to make it a solid seal at the same time. However, these are based on product specifications for tailor-made and in the custom mold.

Use the mold to cut the specified material out of the specified shape to match the customer’s needs during assembly.

The various types of pressure-sensitive and non-pressure-sensitive materials and various film materials such as industrial tapes, electronic tapes, medical tapes, polyester films, Kapton, Teflon, vinyl, plastic plate, foam, circuit boards and fish paper etc. The products can be made into rolls, or they can be made into pieces independently, or provided by your specification.

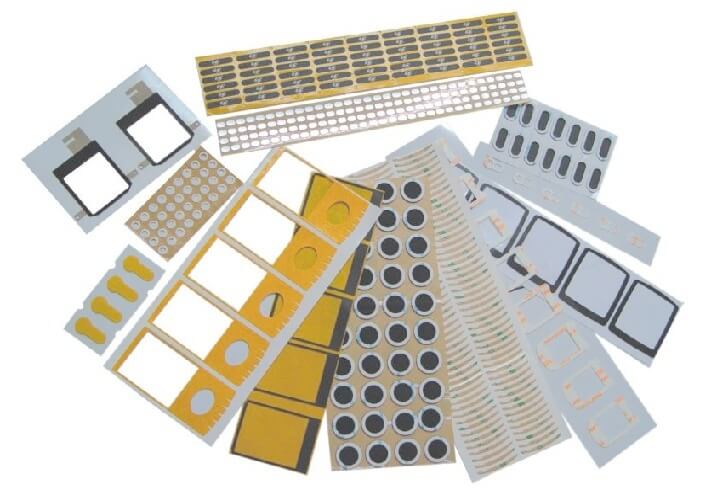

The following die-cutting products, punching according to customer requirements to cut a variety of shapes and selection!

1.double-sided adhesive tape

Can be used in various parts of the paste, bonding, fixed, conductive, insulation and so on.

Material suppliers: Jintuo, 3M, TESA, NITTO and China variety of single and double-sided tape. Used in a variety of components between the insulation, vibration-proof, sealed, dust-proof and so on.

2.Foam

Product name:

Foam / CR / XPE / EVA / IXPE and other foam molding materials

PORON / EVA / XPE / CR / NR and other foam products.

PORON – Micropore polymer.

Application industries: computer peripherals, NOTEBOOK, DVD, CD-R, SCANNER, PDA, digital cameras, mobile phones, cars, air conditioners, audio, tape recorders, tape factory, etc.

Usage: dust proof, shock proof, sound-absorbing, shock absorption, electrical conductivity, insulation, EMI, slip wear, thermally insulating, anti-static etc.

3. Conductive shielding composite material categories

Main features: conductive shielding, conductive side of the insulation, double-sided insulation and other.

Main materials: imported and domestic conductive copper foil (CU), aluminum foil (AL), and Cu-Al Mylar composite material (CU-PET, AL-PET), EMI and other composite materials.

4. Reflective light diffuser categories

Main functions: astigmatism, reflective, dark and so have a variety of different thickness, different transmittance of the parts.

5.Others

Other special requirements of the die-cutting parts and special electronic materials

Product Features:

Paste, fixed, conductive shielding, insulation, fire prevention, block light, astigmatism, shading, reflective, high temperature, vibration damping, sealing, protection, dustproof, abrasion resistance, spray masking, heat insulation, sound insulation, filtration and so on.

Applications:

Mobile phones, digital cameras, computers and accessories, printers, fax machines, audio equipment, cars, DVD, backlight equipment, communications equipment, air conditioners, refrigerators, lighting, toys, sporting goods, stationery and other electronic appliances.

I like how you mentioned that die-cutting can be made using a flatbed. My uncle mentioned to me last night that his friend is looking for a custom die-cut products manufacturer for his upcoming project and asked if I have any idea what is the best option to do. Thanks to this informative article and I’ll be sure to tell him that it will be much better if they consult a trusted die-cut products manufacturer company as they can answer all his inquiries.

Dear John

Thank you for your kind comment. Hope it can be of any help.

Best regards

Jintuo Adhesive Products